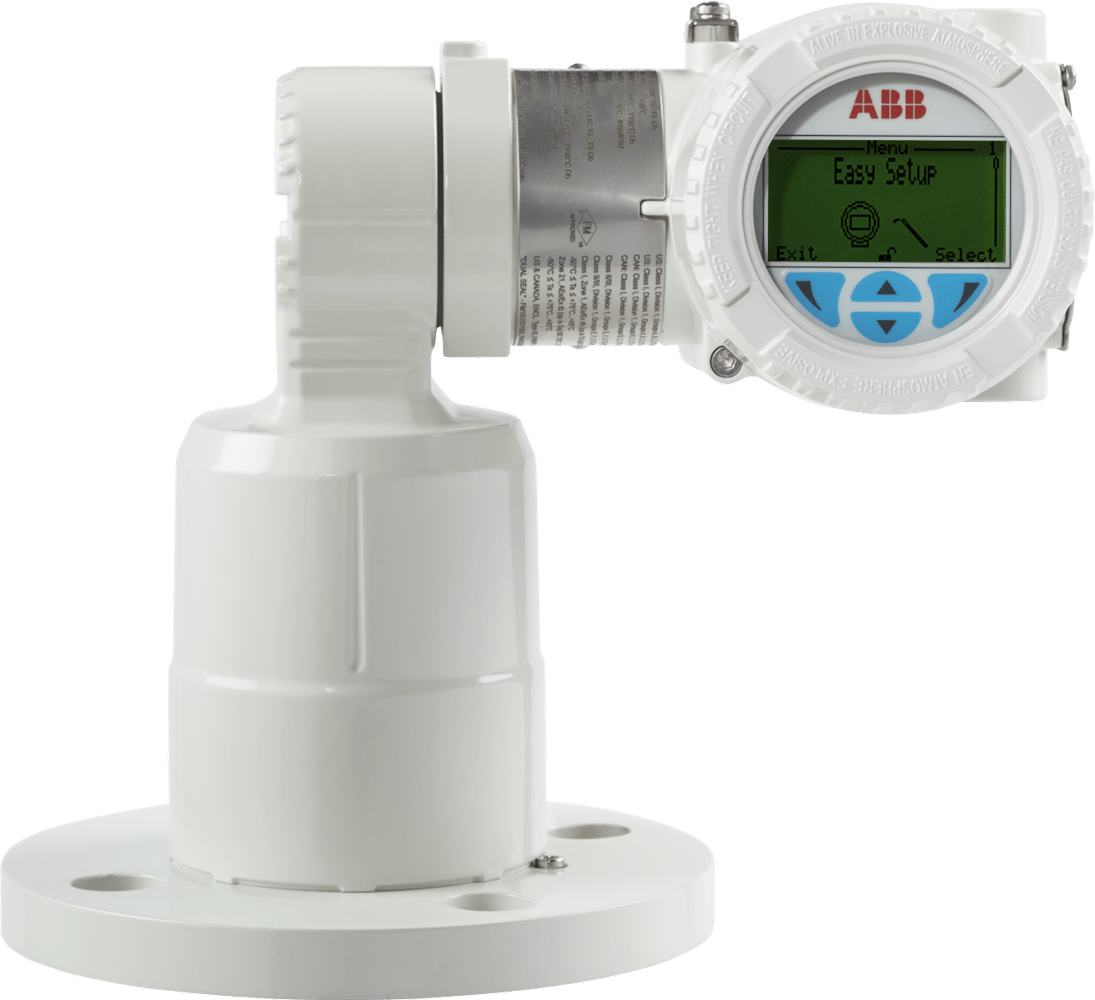

ABB Laser Level Transmitter LLT100

Level Measurement Revolution

Lasers have changed the world of level measurement, offering many benefits over traditional non-contact instruments. With its narrow laser beam, the LLT100 can avoid obstructions and be installed near vessel walls or in tanks with blades, grates or grids. The laser transmitter measures continuously, providing rapid surface change tracking. Advanced signal processing delivers reliable measurements, even in the presence of mixers and dusty, foggy, limited environments. In industries where accuracy and reliable level measurement is crucial, the rugged LLT100 will become a valuable member of your team.

- Simple to Setup

- No Maintenance

- Low Cost of Ownership

- No Calibration Necessary

- Fast and Flexible Installation

- Dust And Fog Penetration Capabilities

- 2-Wire Powered and Hart 7 Communication

- Non-Contact, Continuous Level Measurement

- Precise Measurement of Solid or Liquid Surface

- Multiple Approvals, Including FM, CSA, SIL 2, FDA

- Designed For Industrial Applications and Harsh Environments

- Measures Level, Distance, and Position Over Short and Long Ranges

LLT100 KEY FEATURES

Laser Design

The LLT100 utilizes an eye safe, Class 1 laser beam. The beam angle is 0.3-degrees, providing accurate level measurement in narrow or crowed vessels. This allows users to install the transmitter outside of the process, away from hazardous zones, areas prone to flooding, or mechanical devices.

High Accuracy

With a resolution of 5 mm (0.2-in) and typical accuracy of +/-11mm (0.4-in), the LLT100 provides highly accurate and repeatable measurements, often with better resolution and precision than traditional methods.

Wide Measurement Range

Measures 2-ft to 100-ft for liquids, 2-ft to 330-ft for solids, and 2-ft to 660-ft for positioning applications, making it suitable for a wide range of vessel sizes.

Digital Signal Processing

Besides providing a single output for level, the LLT100 can transmit additional variables. These device variables can help with predictive maintenance and provide confidence in level measurement.

Hazardous Area Approvals

Available with approvals of CE, ATEX, IECEx, FM, 3A for use in hazardous areas, such as dusty or explosive atmospheres.

sludge storage silos | bar screens | sump pumps | wet wells | lift stations | dry chemical storage | odor control | biogas tank levels

LLT100 KEY BENEFITS

Reduced Maintenance

Because it operates without any physical contact with the measured material, there is no wear or tear on the sensor, eliminating the need for frequent cleaning compared to older instruments exposed to the process.

Increased Safety

Unlike other sensors, the LLT100 can be positioned above processes, providing increased safety and easy access. And due to its narrow laser beam, it can measure all the way to the bottom of a well even in the presence of internal structures.

Versatility

Measures levels of various materials, including liquids, slurries, powders and bulk solids, regardless of their dielectric properties or density.

Ease of Installation

Can be installed without shutting down the process or emptying the vessel, as it can be mounted on the top or side of the vessel without intrusion.

Longer Operating Life

With no direct exposure to the process material, the LLT100 has a longer operating life than traditional instruments, reducing the need for frequent replacements.